Factory directly Cast In Place Concrete Surface Roughening Machine - Pre-curing chamber – Xindadi

Factory directly Cast In Place Concrete Surface Roughening Machine - Pre-curing chamber – Xindadi Detail:

Equipment function

The concrete component pre-curing chamber, through the pre-curing of the prefabricated component, the component quickly reaches the initial setting state, which is convenient for subsequent work..

Equipment feature

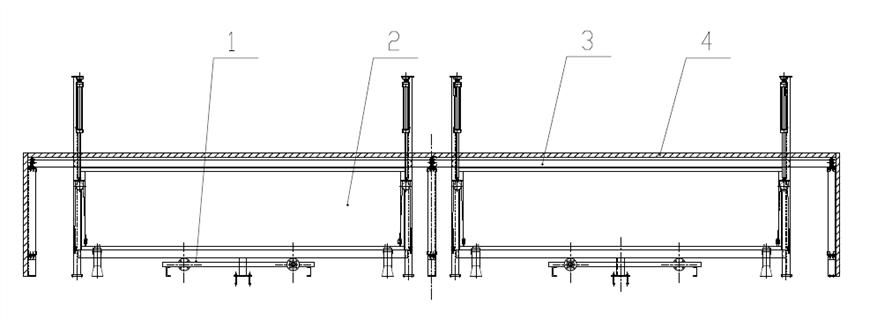

n Pre-curing chamber is set above the conveyor line to facilitate the passing of the pallet with products.

n The equipment adopts dry heat mode, the heating medium is steam, the temperature is controllable, and the difference of the temperature is small

n The opening method of the curing chamber door is pneumatic control, the opening action is rapid and stable

n The pre-curing chamber door opening and the pallet conveyor line can be interlocked, safe and reliable

Equipment composation

n Pre-curing fram

n Pre-curing chamber door

n Temperature Control System

n Insulation system

The main technical parameters

Pallet size:4m*9m 3.5m*9m

Structure type: Bearing type;non-bearing type

Equipment height: 2034mm; 1630mm

Number of stations: optional

Way of heating:Dry steam heating

Insulation material: Polyurethane composite board

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Factory directly Cast In Place Concrete Surface Roughening Machine - Pre-curing chamber – Xindadi , The product will supply to all over the world, such as: Orlando, Dominica, Bhutan, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.