Factory made hot-sale Carousel Line Concrete Component Pallet Surface Roughening Machine - Flatting machine with vibrating – Xindadi

Factory made hot-sale Carousel Line Concrete Component Pallet Surface Roughening Machine - Flatting machine with vibrating – Xindadi Detail:

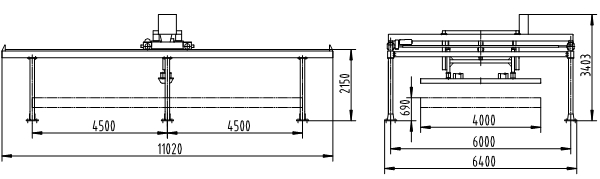

The vibrating leveling machine is used to vibrate and level the concrete poured by the distributing machine. The vibrated and leveled concrete components have a flat surface and a dense and uniform interior, which is conducive to improving the strength and durability of the concrete.

Equipment feature

■ While moving along the X direction, the leveling device alternately swings along the Y direction with a certain amplitude and frequency to rub the concrete surface during the leveling process, which is conducive to the uniformity and density of the concrete.

■ The straightness of the leveling device is high, and there is no deformation or bending during the leveling process, which ensures the flatness of the component.

■ Easy to install and remove the leveling device

■ The leveling machine can be stopped and locked at any position within the lifting stroke, and can be accurately lowered to the preset height by adjustment.

■ Rubber springs are installed between the leveling device and the lifting mechanism, which can effectively reduce the impact of the vibration motor vibration on the main frame.

■ The structure of the whole machine is good in rigidity, stable and durable.

■ Remote control, stable control and easy operation.

Equipment composation

Standard item

■ Steel structure

■ Walking mechanism

■ leveling mechanism

■ Electrical control system

■ Remote control device

Optional item

□ Cross-line selection

Technical Parameters

X direction walking speed 10~15 m/min

X direction walking rate 1.5 kW

Lifting motor rate 0.5 kW

Vibration motor rate 2×0.75 kW

Lifting stroke ≮300 mm

Total rate 3.5 kW

Equipment weight 3750 kg

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory made hot-sale Carousel Line Concrete Component Pallet Surface Roughening Machine - Flatting machine with vibrating – Xindadi , The product will supply to all over the world, such as: Qatar, Juventus, Argentina, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!