Hot sale Ready Mix Concrete Mould Cleaning Machine - Pallet Circular Production Line – Xindadi

Hot sale Ready Mix Concrete Mould Cleaning Machine - Pallet Circular Production Line – Xindadi Detail:

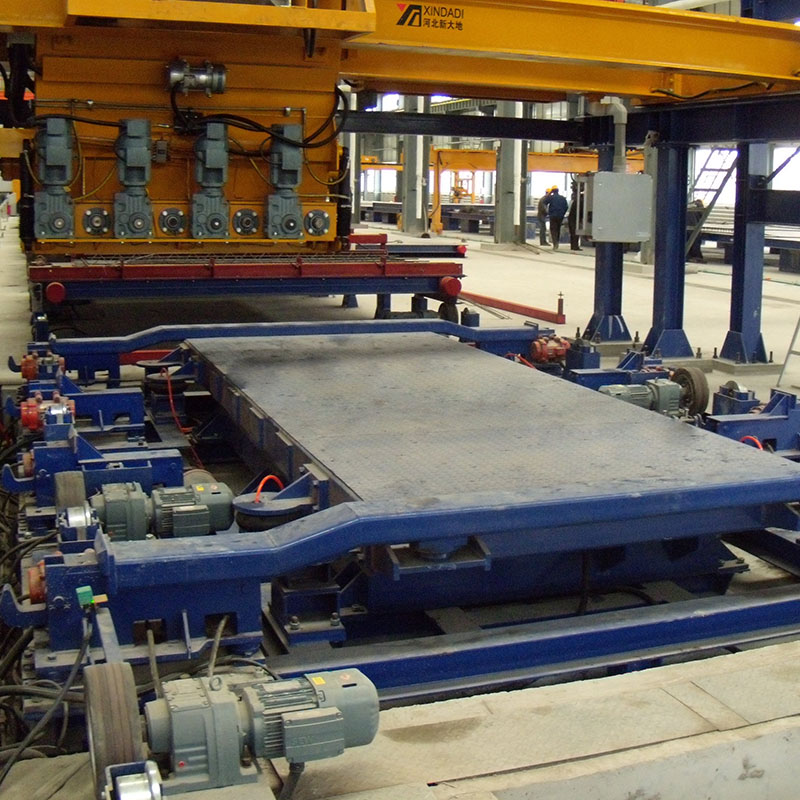

XINDADI pallet circulation systems enable optimum material flow. They therefore play a central role in the optimisation of production processes for cost-efficient precast concrete production.

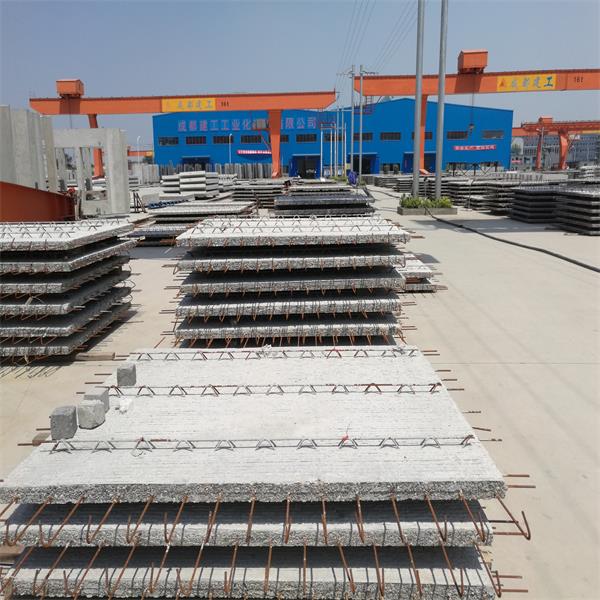

A pallet circulation system for the production of diverse precast concrete parts is always planned individually as a flow production plant. The planning of the material flow and the design of individual workstations depend on the precast concrete parts to be manufactured, for example: floor slabs, double walls, solid walls, sandwich walls or façade elements. Of course, numerous special components can also be manufactured efficiently in our circulation systems.

Increase of profitability by production automation

An optimised manufacturing organisation is created by dividing the entire production process into individual work steps. Cost-efficiency is increased through production automation. This is done by mechanising individual workstations and equipping them with automation components. So, for example, pallet circulation systems are equipped with concrete spreaders, shuttering robots and powerful reinforcement manufacturing facilities. As the formwork technology determines the quality of precast concrete parts, the shuttering profiles and shuttering pallets are continuously treated with pallet cleaners and pallet oilers. The shuttering profiles are perfectly matched to the existing conditions and to the system.

Our varied production range allows us to equip our pallet circulation systems with the latest production and formwork technology and to optimally match these technologies with each other. To manufacture products with different production cycles, the pallet circulation system is moved to specially equipped buffer stations by means of a central transfer table.

Our central main computer technology allows our users to control and monitor the production process according to the current standards of industry 4.0.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Hot sale Ready Mix Concrete Mould Cleaning Machine - Pallet Circular Production Line – Xindadi , The product will supply to all over the world, such as: Maldives, Rotterdam, Sri Lanka, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.