Leading Manufacturer for Curing Chamber - Side shifter – Xindadi

Leading Manufacturer for Curing Chamber - Side shifter – Xindadi Detail:

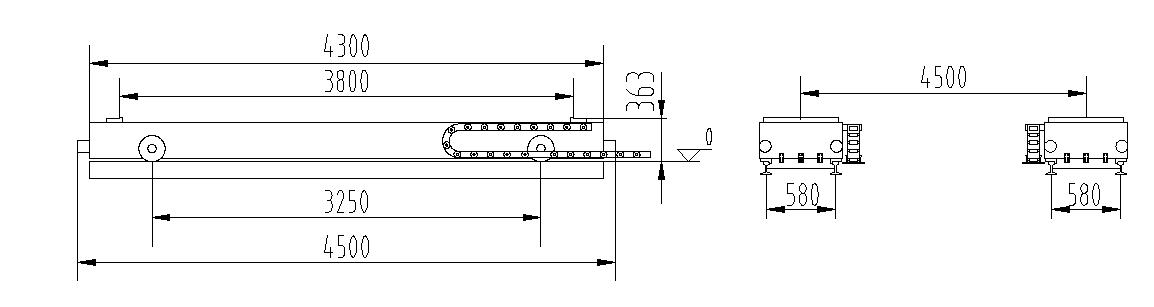

The side shifter is used for the transfer of the pallet on the conveyor line, and pallet is transferred from one side of the conveyor line to the other side for the next process.

Equipment feature

n The side shifter are generally used in pairs.

n The hydraulic system controls the hydraulic lifting cylinders at both ends of the car body to rise,

Jacking up the pallet, the driving device drives the car body to run. After reaching the predetermined position, the hydraulic lifting cylinder down and places the pallet on the roller frame line

n The equipment adopts a servo control system, which can ensure that the car body runs synchronously, smoothly and at an average speed, and the start and stop positions are accurate and the synchronization is good.

Equipment composation

n Car body

n Hydraulic system

n Electronic control system

The main technical parameters

Motor rated total power: 8kW

Bearing capacity: 30T

Lifting oil cylinder stroke: 80mm

Car body speed: 0~0.5 m/s

Car gauge: 580mm

Equipment weight: ≈2000kg

Product detail pictures:

Related Product Guide:

We emphasize development and introduce new products into the market every year for Leading Manufacturer for Curing Chamber - Side shifter – Xindadi , The product will supply to all over the world, such as: Porto, Belarus, Detroit, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.