Lowest Price for Battery Mould Design - Pallet Tilting Machine – Xindadi

Lowest Price for Battery Mould Design - Pallet Tilting Machine – Xindadi Detail:

★Equipment function

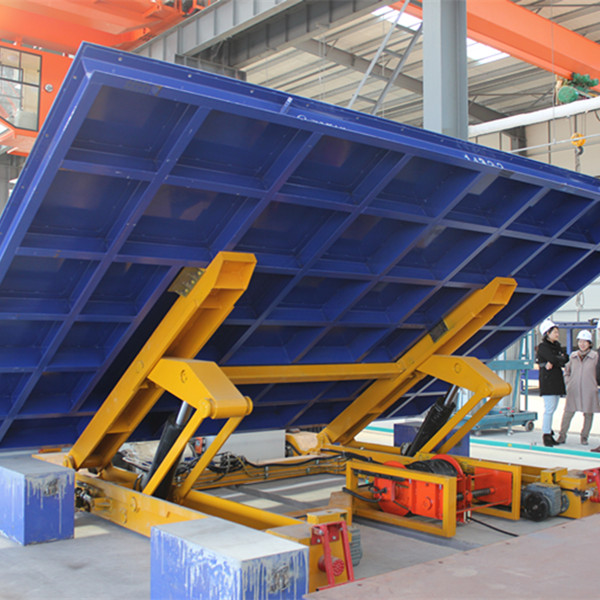

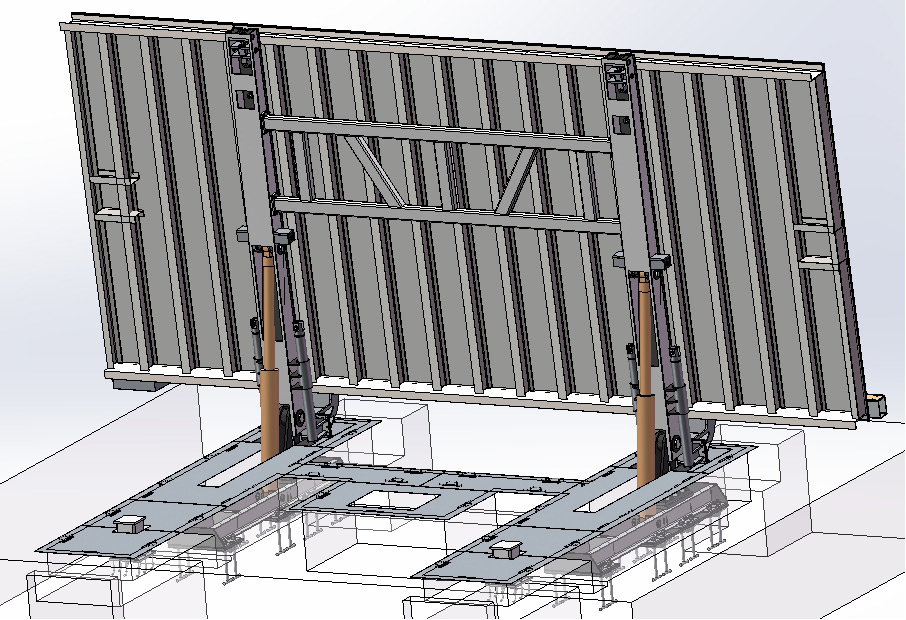

Tilting machine is used for turning over pallet with PC components in production line. After the mould removal is completed, the tilting table turns the pallet and PC components to nearly 90° to ensure that the PC components are not damaged during the lifting process.

★Equipment feature

The component supporting beam can prevent the component from falling off when turned over, and the top supporting device can realizethe component supporting at any position within 400mm of the edge of the pallet.

1.The two turning arms realize the synchronous turning of the two turning arms through a high-precision hydraulic system.

2.The turning moment of the turning machine is large, which ensures that the beam can rotate smoothly in the predetermined direction when the pallet and the PC component are turned.

3.The hydraulic system guarantees the stability of hydraulic reversal and the start and stop at any position within the working range.

4.The turning and jacking of the tilting table adopts hydraulic locking device, and the turning and jacking action is safe and reliable.

5.The control uses related buttons on the control panel, which is simple and convenient.

★Equipment composition

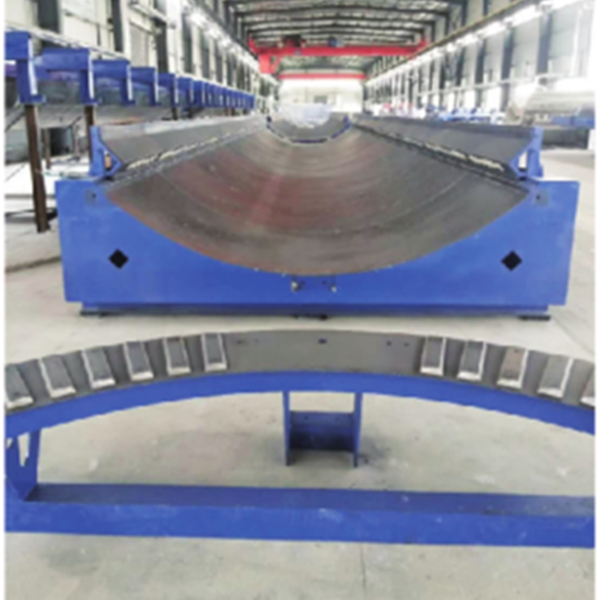

1.Tilting support

2.Tilting arm

3.Jacking device

4.Component bearing beam

5.Locking device

6.Small support

7.Hydraulic system

8.Electrical system

9.Bearing beam support

★The main parameters

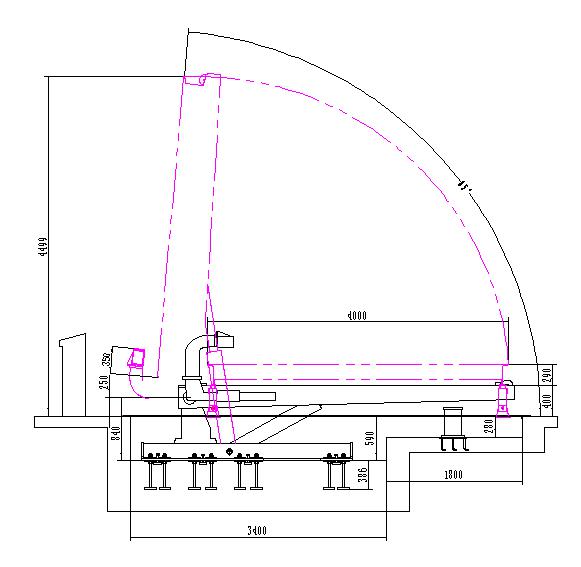

1.Tilting load ≤25t

2.Tilting angle: 0°~85°

3.Tilting time:up 90s down 60s

4.Tilting synchronization: ≤3%

5.Hydraulic system pressure:16MPa

6.Fuel tank capacity:270L

7.Motor power:11KW

8.Total weight: 5.0t

9.Power:380V±20%

★Standard accessories and optional accessories (bearing beam support)

Optional item:Inner wall pannel and outside wall pannel process

Distance between large beam and pallet 34mm-114mm.

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★System Introduction

The production system for precast concrete elements has circulation production system,prestressed production system,stationary production system,flexible production system and nomadic production system.

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for Lowest Price for Battery Mould Design - Pallet Tilting Machine – Xindadi , The product will supply to all over the world, such as: Macedonia, Durban, Lithuania, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!