With the smooth rolling-off of the last batch of sleepers for the Mining Line Project of the Western Railway in Algeria undertaken by China Railway Construction Corporation (CRCC), the sleeper precasting task of the first standardized railway concrete sleeper plant built by a Chinese enterprise in the Sahara Desert has been successfully completed. This milestone marks a major breakthrough for the project in realizing the integrated innovation of Chinese and international heavy-haul railway standards, as well as in promoting the full industrial chain application of China’s standard technologies for prestressed concrete sleepers for heavy-haul railways in North Africa, laying a solid foundation for the full-line connection of the project.

Guided by the principles of standardized plant layout, circular production lines, automated concrete mixing and prestressed tensioning, and intelligent curing, the Chinese constructors have deployed two automated circular sleeper production lines. In the construction process, they have adopted a number of innovative construction technologies, including high-precision digitally stamped steel formworks, the long-mold automated production process, and the incorporation of desert yellow sand into dry-hardened concrete. They have undertaken the production of 1.08 million new sleepers, more than 32,000 new bridge sleepers and 98 sets of turnout sleepers for the entire railway line.

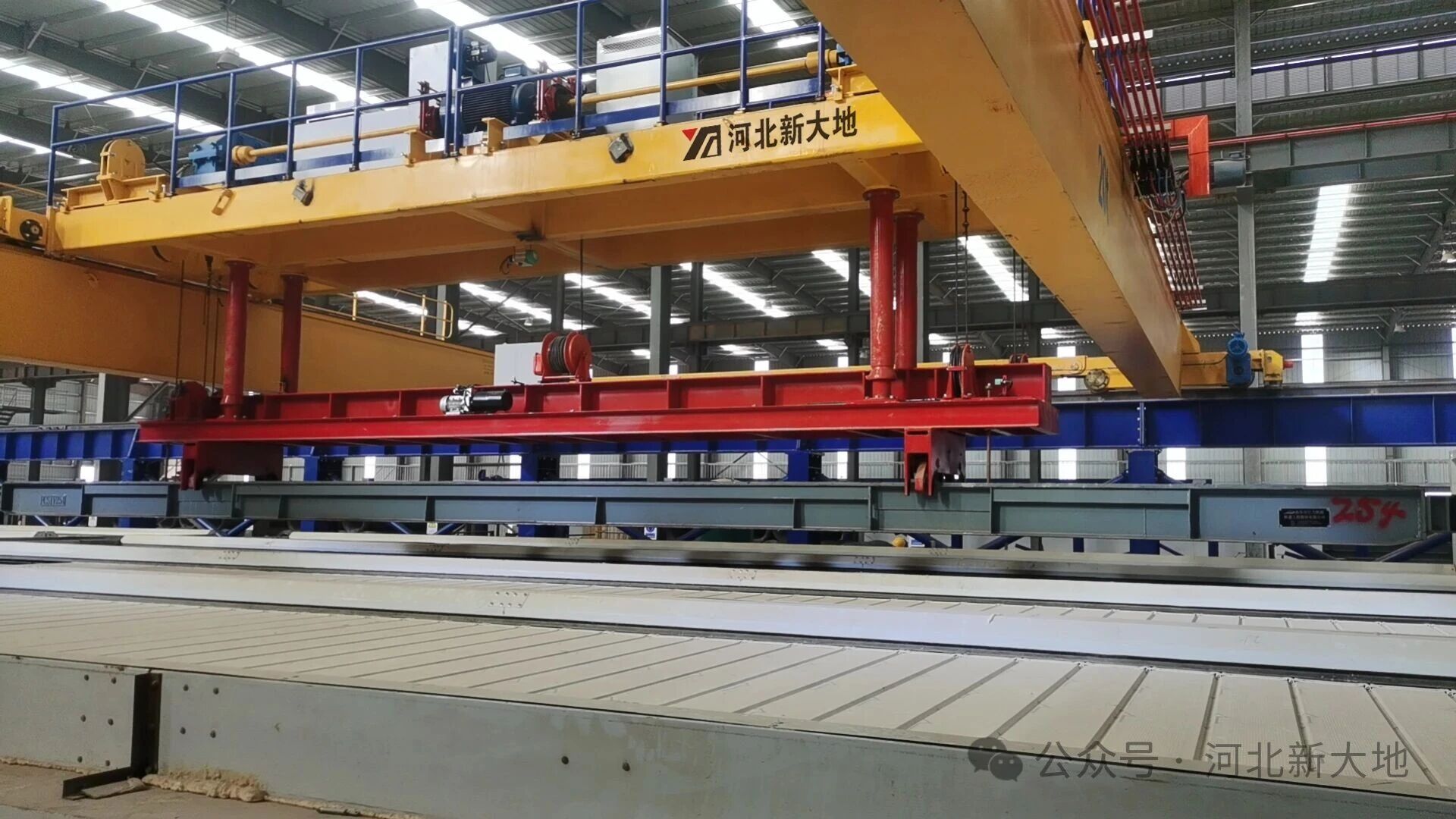

As the core equipment supplier for this project, Hebei Xindadi has provided a complete set of intelligent solutions for sleeper production lines. The production lines integrate fully automatic kiln entry & exit and palletizing machines for moulds, fully automatic turning and demoulding systems, fully automatic sleeper palletizing systems, fully automatic tensioning and releasing systems, as well as SCADA systems, thus achieving full automation, intellectualization and high efficiency of sleeper production.

Chinese and Algerian constructors have overcome the challenges posed by the extreme desert environment, setting a record of a maximum daily output of 5,200 sleepers and a maximum monthly output of 110,000 sleepers. Stringent quality control measures were strengthened throughout the production process, and through self-inspection, type inspection, static load test and other inspection methods, the product qualification rate reached 100% with a high-quality rate of 99%. Abdelkader Djellaoui, the Minister of Public Works and Infrastructure of Algeria, highly commended the plant for its outstanding market adaptability and comprehensive support capacity during his research visit to the sleeper plant.

The Mining Line Project of the Western Railway in Algeria is an important part of the follow-up outcomes of the meeting between the two heads of state in July 2023, and a landmark project of the joint construction of the Belt and Road Initiative by China and Algeria. With a total length of 575 km, the whole line links Béchar Province and the El Gara Djebilet iron ore mining area in Tindouf Province of Algeria. Upon completion, the project will open up the transportation corridor connecting the mining area, industrial zones and ports, and boost the transportation and economic development in southwestern Algeria.

Post time: Dec-27-2025