Zhengding High-tech Zone Entrepreneurship and Innovation Center is a modern science and technology park that integrates talent, technology, environmental protection, culture, communication, and living facilities. It is an important component of the whole industry chain incubation carrier. Currently, it has been completely completed and is undergoing internal decoration.

The main building of Zhengding Entrepreneurship and Innovation Center adopts pre-stressed double T as the construction method for the floor and roof panels. The main building has one underground floor and nine above-ground floors, with a total area of 9600 square meters using double T panels. The floor constant load is 4.2 kN/m², the live load is 5 kN/m, and the partition wall load on the floor is 10 kN/m, which can accommodate large-scale testing equipment. This is the first commercial office project in Shijiazhuang to apply pre-stressed double T technology.

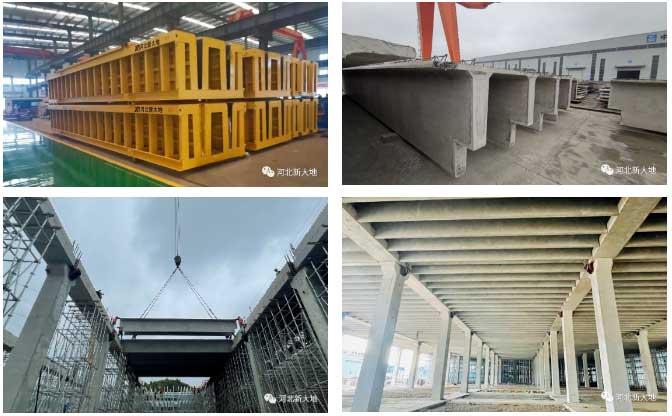

The pre-stressed double T panel production line

The pre-stressed double T panel production line adopts the long-line platform and pre-tensioning method for production. The molds used are special steel molds, breaking through the conventional single mold production method and realizing an expandable combination long-line platform production method.

Characteristics of the pre-stressed double T panel production line:

Characteristics of the pre-stressed double T panel production line

The pre-stressed double T panel production line adopts the long-line platform and pre-tensioning method for production. The molds used are special steel molds, breaking through the conventional single mold production method and realizing an expandable combination long-line platform production method.

Characteristics of the pre-stressed double T panel production line:

1. Self-supporting: The production line mold can withstand the pre-stressing tensile force, different from the traditional double T molds.

2. Combinable: Utilizing the same set of platform and molds, different height, width, and length double T panel components can be produced by adjusting the rib height and plate width.

3. Portable: The production line can be quickly installed and put into production at the construction site. The production equipment can be moved, similar to the nomadic style of a Mongolian yurt. After the project is completed, the equipment can be disassembled and transported to the next construction site, reducing the transportation cost of the components.

4. Long-line platform: The mold of the production line is a long-line mold platform consisting of two endheads and several intermediate parts with a certain length. It can be used to produce pre-stressed double T panels, double T panels with skylights, externally suspended double T panels, etc.

Products and Applications

of the pre-stressed double T panel production line

The double T panel has a cross-section that resembles two “T” shapes, consisting of a compression panel and two rib beams. It has good structural mechanical performance, clear transmission hierarchy, and concise geometric shape, making it an economical load-bearing component for large spans and coverage areas. It has the advantages of corrosion resistance and environmental friendliness, aesthetic durability, convenient installation, and time-saving construction.

In single-layer, multi-layer, and high-rise buildings, double T panels can be directly placed on frames, beams, or load-bearing walls, serving as floors or roofs, load-bearing or non-load-bearing walls. It is widely applicable to industrial and various civil buildings, such as large factories, restaurants, exhibition halls, shopping malls, multi-storey parking garages, grain warehouses, etc.

Applications in Hebei Xindadi projects:

1. Shenzhen-Shantou Special Cooperation Zone Shengteng Technology Industrial Park Co., Ltd.

The production line adopts a long-line pre-stressed double T panel complete equipment set, completing the construction of a 27,000 square meter industrial plant. It witnesses the development process from concept to product to the building, making it the first long-line, combinable pre-stressed double T panel production line in China.

The project uses fully prefabricated concrete components, using self-made concrete columns, double T wall panels, and double T roof panels to construct multi-story office buildings, fully demonstrating the beauty of architectural art.

2. Shanghai City Construction Industry (Group) Co., Ltd.

The PC plant of this project is constructed using fully prefabricated concrete components, including self-made concrete columns, concrete overhead beams, and concrete double T roof panels, with two different lengths of 27 meters and 30 meters for the roof panels.

3. Wenzhou Zhengli Construction Technology Co., Ltd.

The project applies the expandable combination long-line platform production system to produce pre-stressed concrete double T panels of different specifications, used in the construction of an 18-meter multi-story prefabricated plant. This is the first four-story pre-stressed double T panel plant in the country and the first multi-story assembly plant project in Wenzhou.

4. China Construction Technology (Guizhou) Co., Ltd.

Four sets of pre-stressed concrete double T panel complete production lines provided by Hebei Xindadi are applied to the construction of the Xuyun Technology Special Wood Industry Park – comprehensive office building, production plant, warehouse, underground parking, grain warehouse, etc., in Guiyang City.

Post time: Aug-28-2023