Recently, the first precast success of the fully automatic hydraulic box girder mold, constructed by Hebei Xindadi Mechanical and Electrical Manufacturing Co., Ltd., was achieved in Heilongjiang Iron Investment. This project is located in Yichun City, Heilongjiang Province, and is an important part of the Heha Expressway. It is the first production line in the region to use fixed side molds and mobile bases to produce box girders.

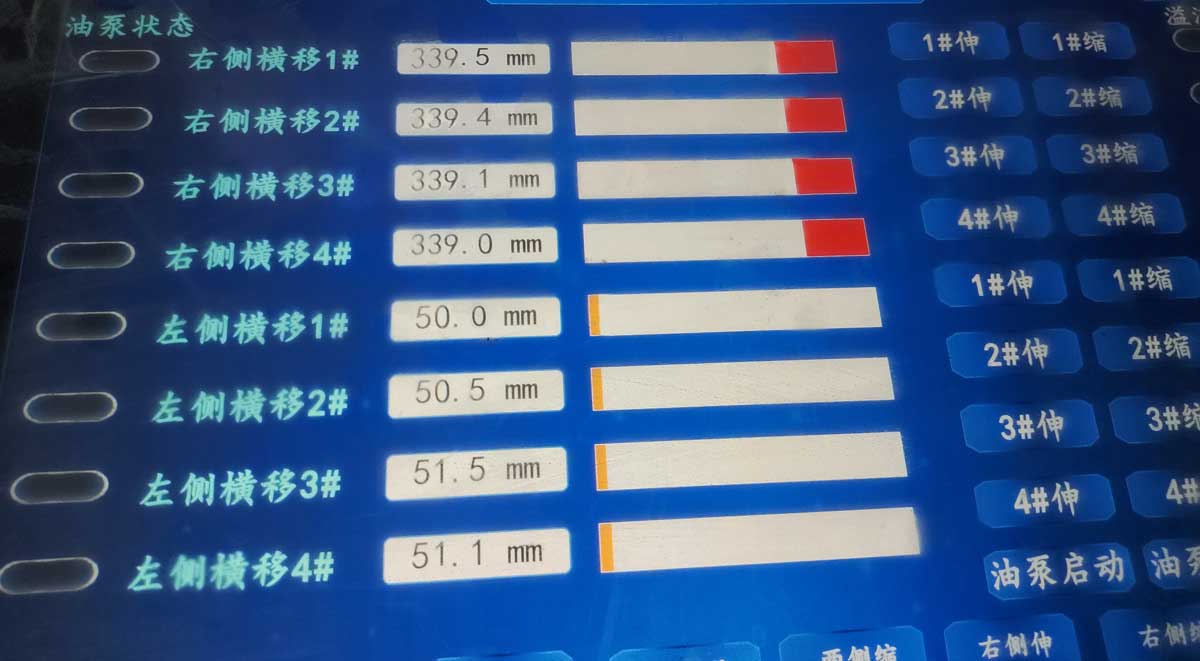

The production line utilizes a hydraulic automatic box girder mold with the industry’s first “three-separator side mold” integrated automatic demolding function. The box girder mold adopts modular design and features split separator end plates. The hydraulic cylinder adopts a digitized visual control program for stroke, with multiple cylinders synchronously operating for smooth opening and closing. This enables fast mold installation and efficient production of box girders, allowing for quick delivery of products. The mold is made of polished stainless steel, resulting in smooth and shiny product components. The attached compaction uses an automatic multi-stage variable frequency vibration compaction system, which allows for free selection of vibration areas. The entire operation is controlled using a fixed workstation and tablet computer, providing convenient and efficient operation.

The production line adopts an intelligent production system control, which monitors and predicts the production process, promptly identifying and solving any issues that may arise. This helps improve production efficiency, product quality, and stability.

- Stainless steel mold surface polishing, resulting in smooth and shiny product components

- Stainless steel mold surface polishing, resulting in smooth and shiny product components

- Digitized visual control program for hydraulic cylinder stroke

- Overall adoption of a fixed workstation and tablet computer dual operation control mode.

- Overall adoption of a fixed workstation and tablet computer dual operation control mode.

Hebei Xindadi provided a full range of services including process planning, equipment design, production manufacturing, equipment installation and commissioning, equipment training, and after-sales service for Heilongjiang Iron Investment. The successful operation of this project signifies another solid step taken by Hebei Xindadi in the field of road and bridge engineering.

For 18 years, Hebei Xindadi has focused on research and development in the field of “energy-efficient prefabricated concrete green and intelligent manufacturing technology and equipment.” Its leading product is “energy-efficient green prefabricated concrete building material automated equipment and intelligent management systems,” which are widely used in fields such as rail transportation, prefabricated buildings, municipal infrastructure construction, road and bridge engineering, and new energy. It has provided over 1,000 precast concrete production systems to more than 600 clients at home and abroad, making it a leader in the domestic market.

Through its advanced software and hardware capabilities, excellent service consciousness, and efficient operation management, Hebei Xindadi is committed to promoting industrial development and industry upgrading, aiming to become a world-leading company in prefabricated concrete processing equipment and technology.

Post time: Jul-24-2023