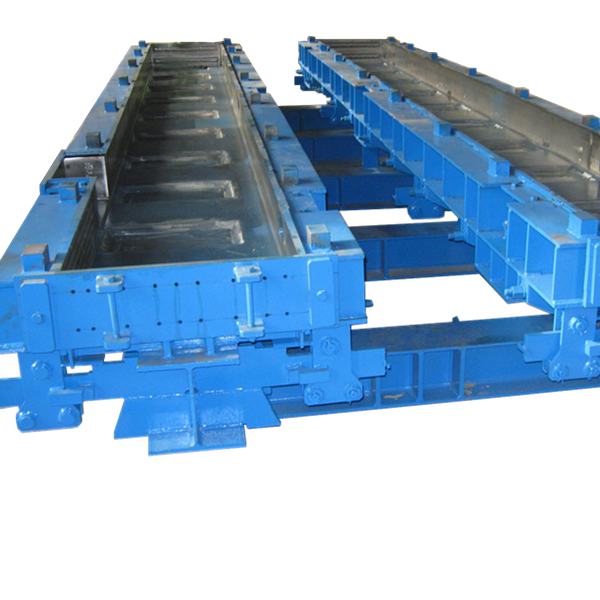

Top Quality Precast Panel Wall - SK2 Double-block Sleepers Production Line – Xindadi

Top Quality Precast Panel Wall - SK2 Double-block Sleepers Production Line – Xindadi Detail:

★Company Introduction

Hebei Xindadi electromechanic Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★System Introduction

1.Automatic mold circulation system (mold roller conveying).

2. Intelligent cleaning and spraying station.

3. Linkage automatic control of feeding system and distribution system.

4. The auger distributor is uniform, reliable and quantitative.

5. Pit type curing chamber. Automatic mould stacker is used for entering and leaving the chamber.

6. The automatic mould stacker is linked with the maintenance control system.

7. The intelligent equipment of each station and the mould conveying system realize signal transmission and automatic.

★Production capacity:

1. Capacity: 2400 pieces/day, 720,000 pieces/year;

2. Working system: double shift system, 10 hours per shift, 300 working days/year;

3. Beat: The production line beat is 4 minutes;

4. Production line type: long mould circulation production line;

5. Mould type: 2×4 type;

6. Model of mixing station: 60

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for Top Quality Precast Panel Wall - SK2 Double-block Sleepers Production Line – Xindadi , The product will supply to all over the world, such as: Madagascar, Finland, Bangladesh, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.