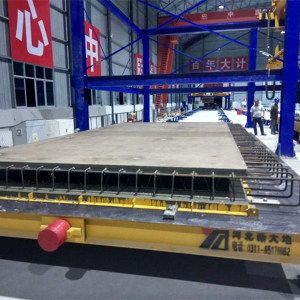

3D Garage Mould

★Product Introduction

The 3D garage mold designed and manufactured by Hebei Xindadi for customers in Inner Mongolia has been successfully debugged in the factory and shipped.

The design engineer and the production department strictly control the production quality according to the process requirements. After the production of all parts is completed, the overall mold is assembled, installed and debugged in the factory.

From customer inquiry to mold delivery, Hebei Xindadi has always adhered to the requirements of “high starting point, high standard, high quality and high efficiency”, and realized the design, manufacture and delivery of 3D garage molds within one month.

★Product Features

1. The internal mold combination is optimized to realize the sequential shrinkage of the internal mold, and the separation of the internal mold from the component, avoiding the reserved draft angle of the component;

2. The outer mold adopts the track opening and closing mold structure, which is convenient for mold removal and fast mold assembly;

3. Increase the steam maintenance measures, significantly shorten the maintenance time and improve the production efficiency.

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★Moulds Introduction

Our company’s moulds include prefabricated building moulds, municipal road and bridge moulds, wind power tower moulds, high-speed railway moulds, mould tables and prefabricated components supporting tooling and hangers.

Prefabricated building moulds include stair moulds, wall panel moulds, special-shaped moulds, beam-column moulds, laminated plate moulds, double-T plate moulds, and 3D house moulds; municipal road and bridge moulds include small and medium-sized moulds, pipe gallery moulds, prefabricated bridge moulds, subways segment moulds; wind power tower moulds include cone-type tower moulds, segmented tower moulds; high-speed railway moulds include double-block sleeper moulds, prestressed sleeper moulds, trapezoidal sleeper moulds, track plate moulds; The pallet contains circulation line pallet, fixed pallet, pre-stressed pallet, customized pallet; prefabricated components supporting tooling and hangers include spreaders, storage racks and transport racks;