Battery Mould

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★Moulds Introduction

Our company’s moulds include prefabricated building moulds, municipal road and bridge moulds, wind power tower moulds, high-speed railway moulds, mould tables and prefabricated components supporting tooling and hangers.

Prefabricated building moulds include stair moulds, wall panel moulds, special-shaped moulds, beam-column moulds, laminated plate moulds, double-T plate moulds, and 3D house moulds; municipal road and bridge moulds include small and medium-sized moulds, pipe gallery moulds, prefabricated bridge moulds, subways segment moulds; wind power tower moulds include cone-type tower moulds, segmented tower moulds; high-speed railway moulds include double-block sleeper moulds, prestressed sleeper moulds, trapezoidal sleeper moulds, track plate moulds; The pallet contains circulation line pallet, fixed pallet, pre-stressed pallet, customized pallet; prefabricated components supporting tooling and hangers include spreaders, storage racks and transport racks;

★Product Introduction

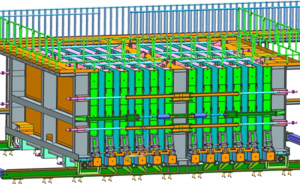

Battery mold production is a process equipment that places several molds vertically, forms several cavities through the movement of the group molds, and then pours concrete into the cavities. and the final maintenance through vibrating,.

The curing of components can be cured by steam, hot water, hot oil or electric energy, and dry heat curing can be formed on one or both sides of the product;

Battery mould are suitable for producing concrete products with smooth surfaces such as interior wall panels;

★ Product Features

1.Fast forming speed and high production efficiency

2.Compact and space-saving

3.Low energy consumption for production, saving resources

4.High molding precision and good physical and mechanical properties

5.Good process stability

6.Strong adaptability of wallboard materials

7.A variety of structural forms can be produced