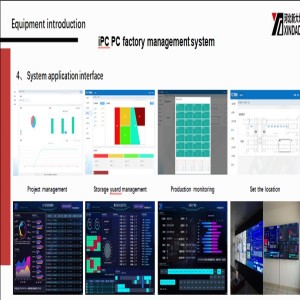

IPC PC Factory Management System

IPC prefabricated component factory management system includes:

①iPC_ExData Hardware data acquisition system platform;

②iPC_MES Concrete prefabricated component manufacturing execution system;

③ iPC_ERP Enterprise resource planning system for precast concrete components;

In terms of function, the system covers all relevant links of PC component production and management. It can realize the functions of PC component three-dimensional structure information extraction, auto matic production scheduling of contract orders, raw material inventory procurement, intelligent production monitoring, integrated quality control, product warehousing and delivery, and also can open up the logistics, business flow and information flow between management, planning, procurement, production and other links.

The above-mentioned system can provide enterprise managers with one-stop management cockpit, convenient production kanban, and real-time monitoring of the production site. It can also provide front-line production personnel with functions such as material procurement, production planning, and product warehousing.

Characteristics of IPC Management System

1.Convenient operation:Simple and convenient cooperative operation between fixed terminal and mobile terminal;

2.Scheduling automation:Based on self-defined multi-dimensional rules, automatically generate scheduling plans and arrange production resources reasonably;

3.Digital, intelligent and lean production:Based on a one-stop centralized cloud monitoring platform, it realizes remote monitoring of equipment, molds, energy consumption, images, etc., and intelligent system linkage;Component information integration and equipment intelligent control with project management as the main line and production process as the core;

4.Quality consistency:Support pre-control, in-process management, post-process, full-process monitoring, and problem tracing;

5.Intelligent storage yard:Realize the informatization of yard management, visualization of component stacking, accurate entry and exit of components, and intelligent analysis of stacking capacity;

6.Management and control integration:With horizontal and vertical integration, supply chain information is realized horizontally, and the integration of upper-level design information and BIM information and lower-level equipment is realized vertically, supporting multi-dimensional processing