Prestressed Long-line Production System for Prestressed Concrete Components

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★System Introduction

The production system for precast concrete elements has circulation production system,prestressed production system,stationary production system,flexible production system and nomadic production system.

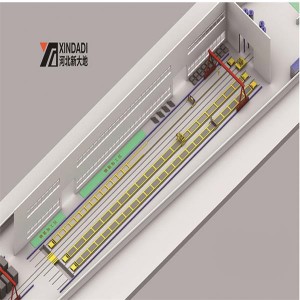

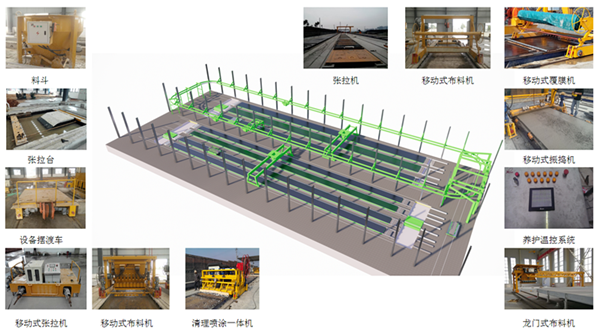

The prestressed production line system usually adopts the production organization mode of long line formwork, and the production of prestressed components is carried out by means of pallet fixation and equipment movement. The production system is mainly composed of production processes such as pallet cleaning, plotter, realease agent spraying , side formwork installation, reinforcement installation, embedded parts installation, distribution and vibration, Component finishing operation,pre- curing, mold removal, reinforcement shearing and tensioning, component hoisting, etc.

★ System Features

The prestressed production line system can improve the production efficiency of prestressed components through the production form of long-line fixed formwork and mobile equipment, and the tensioning efficiency of components can also be improved through the integral tensioning machine; The production system integrates highly automated equipment, automatic maintenance and intelligent tensioning system. The equipment has a high degree of integration and automation, and is suitable for the production of a variety of prestressed components.

★ Machine For System

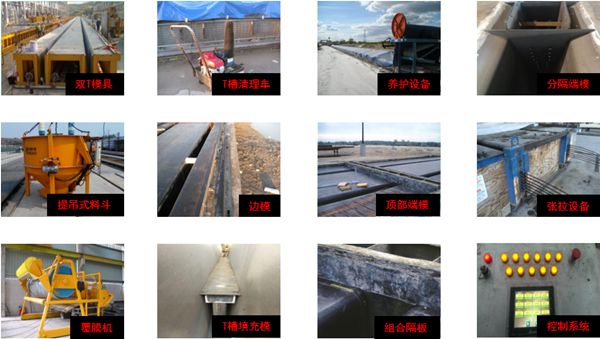

The machine for system are double t-mold, T-groove cleaning vehicle, maintenance equipment, separated end mold, lifting hopper, side mould, tensioning equipment, laminating machine, T-groove filling mold, combined diaphragm, control system and so on.