Stationary Production System for Prefabricated Components

★Company Introduction

Hebei Xindadi electromechanical Manufacturing Co., Ltd. is a world leading technology enterprise of precast concrete processing equipment, and is committed to becoming a competitive enterprise of intelligent concrete processing equipment.The company now has four manufacturing bases in Zhengding, Xingtang, Gaoyi, and Yulin.We wholeheartedly provide customers with technical consultation and special design services for the factory production projects of precast concrete components, and system solutions for the whole life cycle of R & D, manufacturing, installation, commissioning and maintenance of complete sets of equipment, so as to meet the diverse needs of customers and create value for customers in all aspects.

★System Introduction

The production system for precast concrete elements has circulation production system,prestressed production system,stationary production system,flexible production system and nomadic production system.

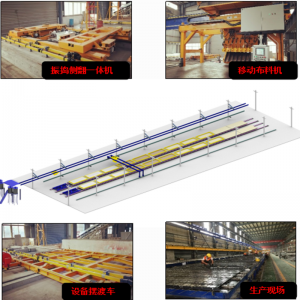

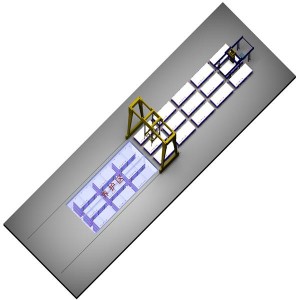

The stationary production system for prefabricated components adopts the mode of stationary pallet and flow of operation equipment and workers to realize the flow production of components.

This kind of production system can complete all kinds of components in prefabricated buildings. At present, it is mainly used for the production of special-shaped components such as PCF board, floating window outer wall, balcony, air conditioning board and so on.

★System Features

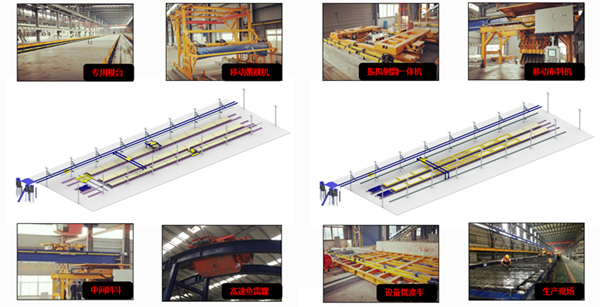

This production system is not limited by the process and can organize production freely. The main operation steps (sequence) include pallet cleaning, formwork assembly and reinforcement binding, concrete distribution, vibration, pre- curing, formwork removal and hoisting, etc.

The production system of prefabricated components is not limited by equipment and has a wide production range. The production line realizes manual replacement and improves production efficiency through the addition of mechanical operation equipment. For example, the high-speed fish tank replaces the concrete tank truck, the mobile distributor replaces the manual lifting hopper, and the mobile shaking table replaces the vibrating rod.

At the same time, the production system is not limited by the site, the process layout is free and the capacity expansion is convenient.

★Machines for System

The machines for the system are special mold , mobile film laminating machine, vibrating rollover machine, mobile distributor,conceying hopper, high-speed torpedo, side shifter an so on.